How Thick Should Soundproofing Mats Be? Material Differences Matter - Choose Right for Effective Noise Reduction

When selecting soundproofing mats, thickness is a key factor, but thicker isn't always better. Material properties, application scenarios, and noise reduction requirements collectively determine the optimal thickness. As an industry benchmark, Vibratech Acoustics achieves the perfect balance between effective noise reduction and space utilization through precise thickness-scenario matching across its full product line. The following detailed analysis combines product specifications with real-world applications:

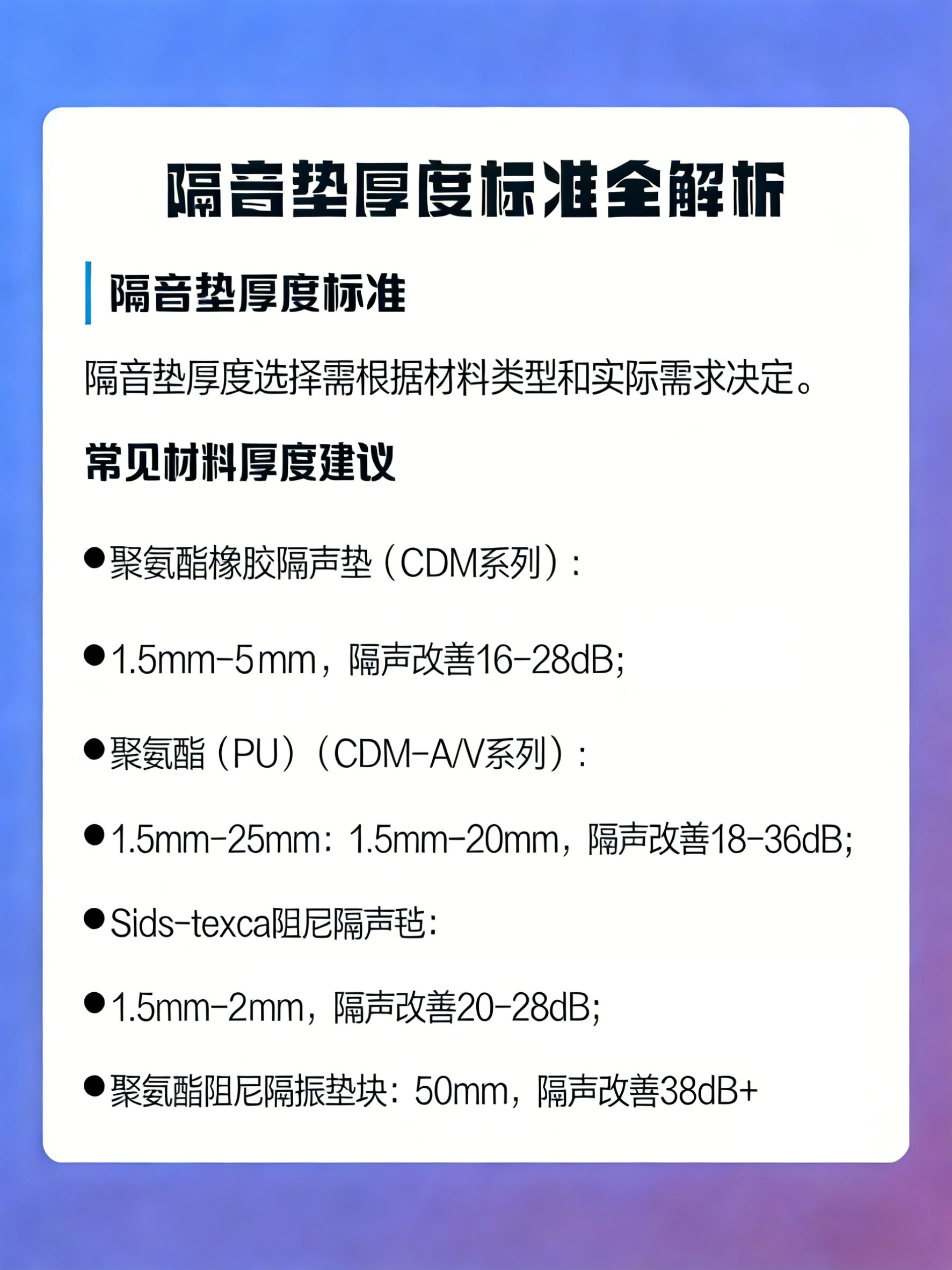

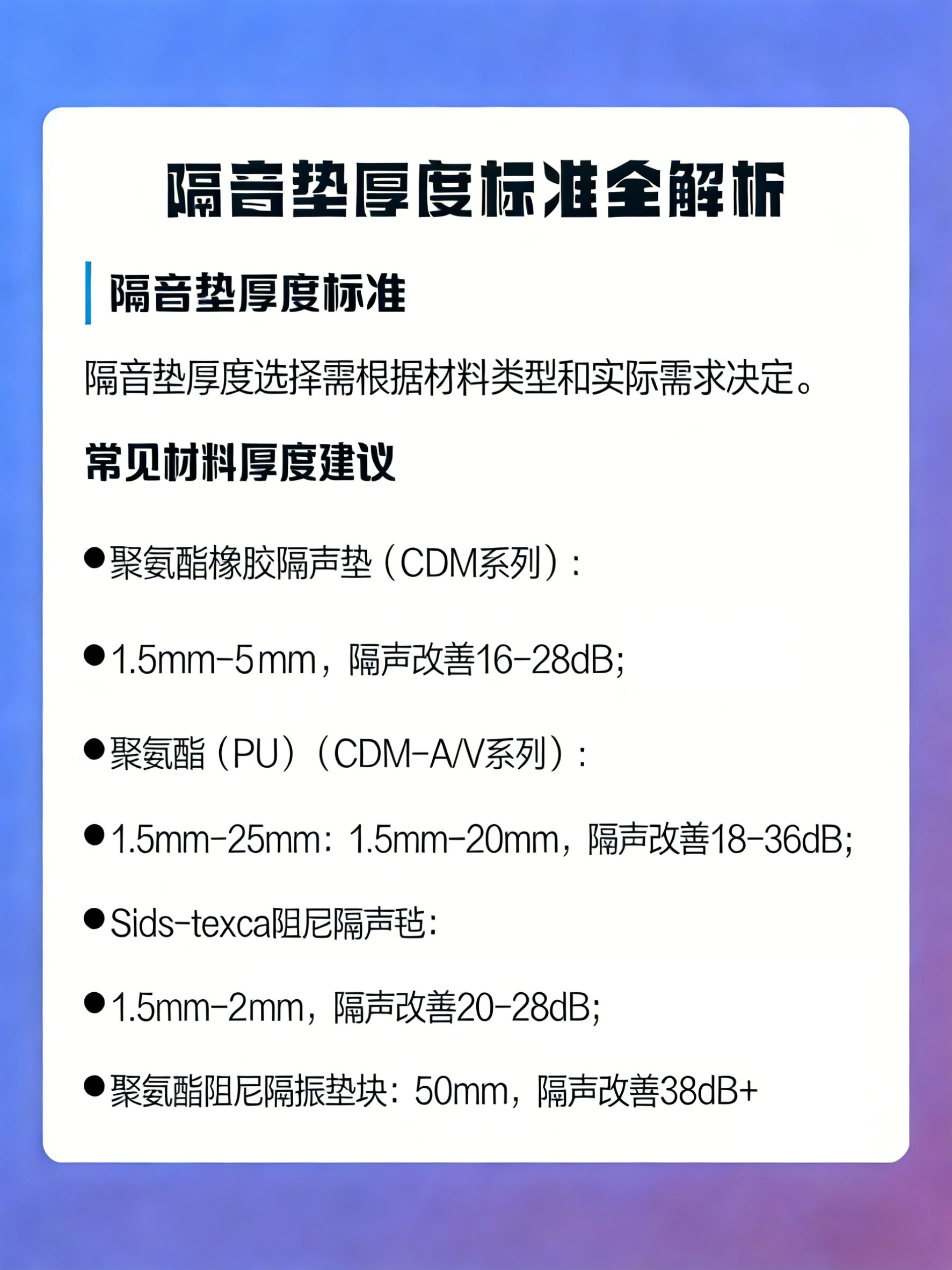

1. Thickness-Performance Correlation Table for Mainstream Material Soundproofing Mats

2. Thickness Selection by Scenario: Precise Matching, No Waste

2.1 Standard Residential / Affordable Housing (Basic Noise Reduction Needs)

-

Core Requirement: Address floor impact noise (footsteps, furniture movement), meet national minimum sound insulation standards (≥70dB impact noise improvement)

-

Recommended Thickness: 1.5mm-3.0mm (Polyurethane Rubber / PU material)

2.2 Luxury Residential / Silent Mansions (Comfort Noise Reduction Needs)

-

Core Requirement: Impact sound insulation ≤60dB, creating a tranquil living environment

-

Recommended Thickness: 3.0mm-5.0mm (Polyurethane Rubber / PU material)

2.3 Five-Star Hotels / Premium Clubs (Stringent Noise Reduction Needs)

-

Core Requirement: Guest room floor impact sound insulation ≤55dB, isolate MEP equipment vibration and external noise

-

Recommended Thickness: 5.0mm (Polyurethane PU material)

2.4 Super High-Rise Buildings / Equipment Rooms (Extreme Noise Reduction Needs)

-

Core Requirement: Address low-frequency vibration and high noise levels, e.g., elevator machine rooms, pump rooms, floating floors

-

Recommended Thickness: 50mm (Polyurethane Damping Vibration Isolation Blocks) + supporting sound insulation system

2.5 Pipe / Wall Sound Insulation (Auxiliary Noise Reduction Needs)

-

Core Requirement: Eliminate airflow noise, pipe vibration noise, enhance wall sound insulation performance

-

Recommended Thickness: 1.5mm-3.0mm (Sids-texca Damping Soundproofing Felt)

3. Key Selection Guidelines

-

Thickness isn't the only metric: The core advantage of Vibratech soundproofing mats lies in their low dynamic/static stiffness ratio, allowing even thin products to achieve efficient noise reduction, avoiding unnecessary costs and space waste from blindly choosing thicker options;

-

Adapt to construction scenarios: Choose 1.5mm thin PU soundproofing mats for prefabricated buildings without compromising construction efficiency; For heated floor projects, 1.5mm-2.0mm polyurethane soundproofing mats are recommended, balancing sound insulation and thermal conductivity;

-

Comply with standards: All products meet national Class I sound insulation standards, with their engineering methods incorporated into multiple regional green building construction atlases. Selection should reference relevant regulatory requirements.

Choosing the right soundproofing mat thickness can precisely address noise issues while maximizing space efficiency. With over 40 patents and 4000+ project experiences, Vibratech Acoustics provides customized solutions from materials to thickness, ensuring "just right" noise reduction effects for every scenario.

4008-693-698

中文版

4008-693-698

中文版

4008-693-698

中文版

4008-693-698

中文版

2026-01-24 10:13:25

2026-01-24 10:13:25