4008-693-698

中文版

4008-693-698

中文版

4008-693-698

中文版

4008-693-698

中文版

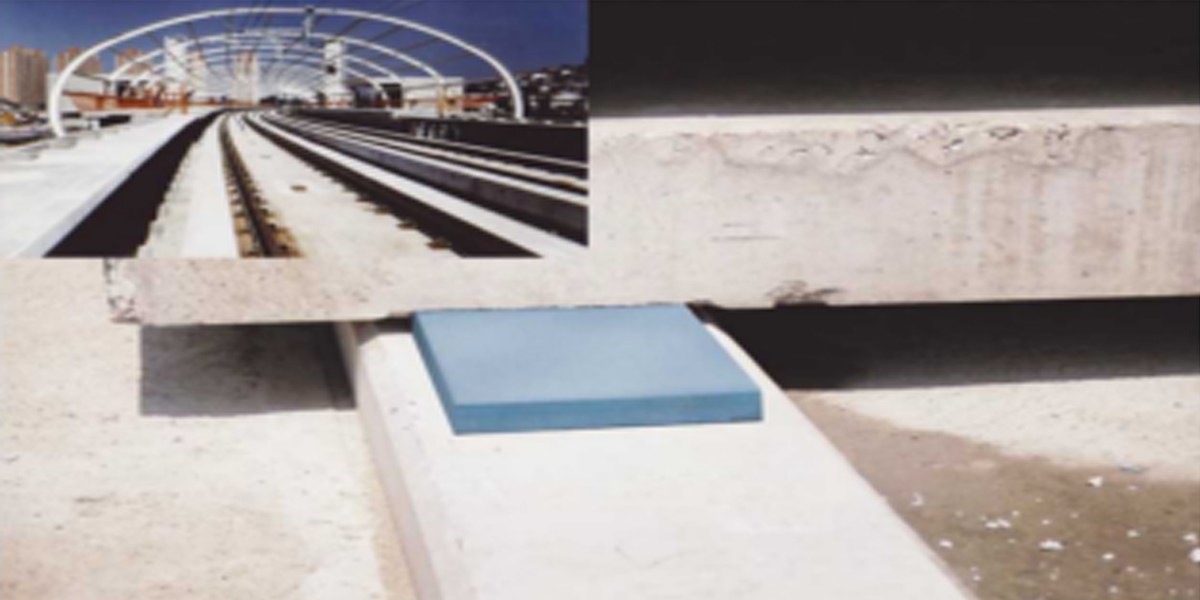

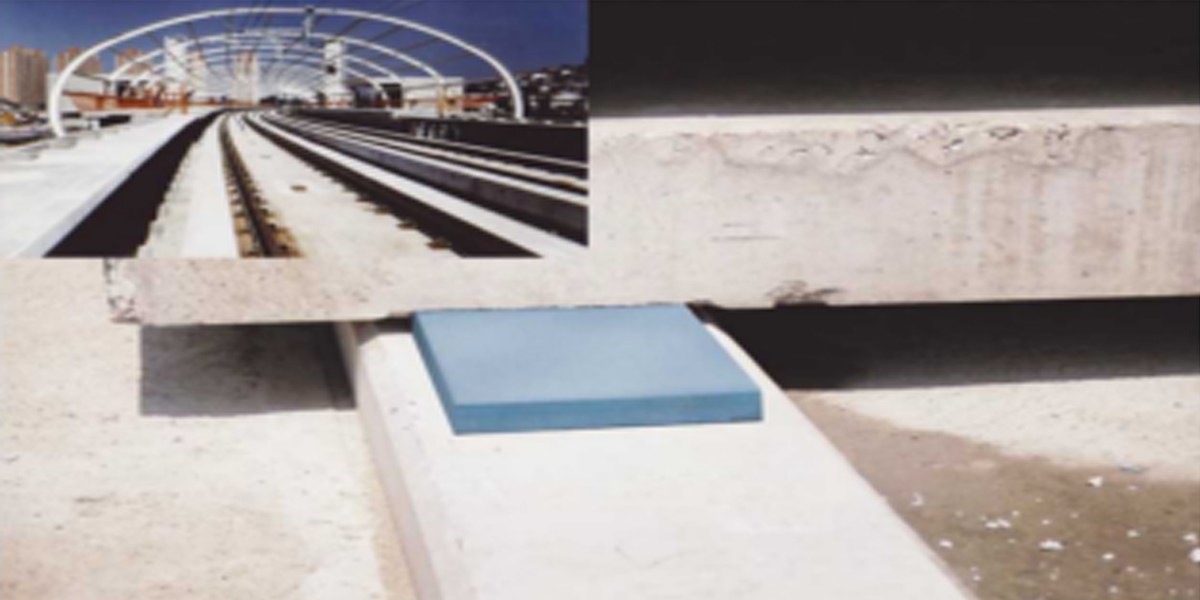

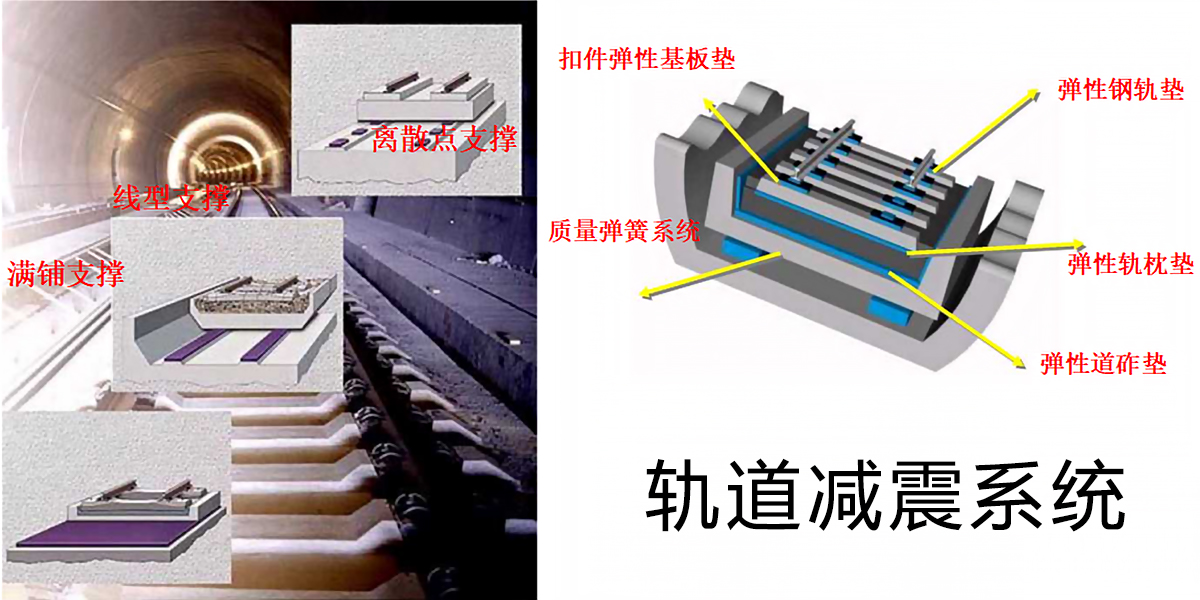

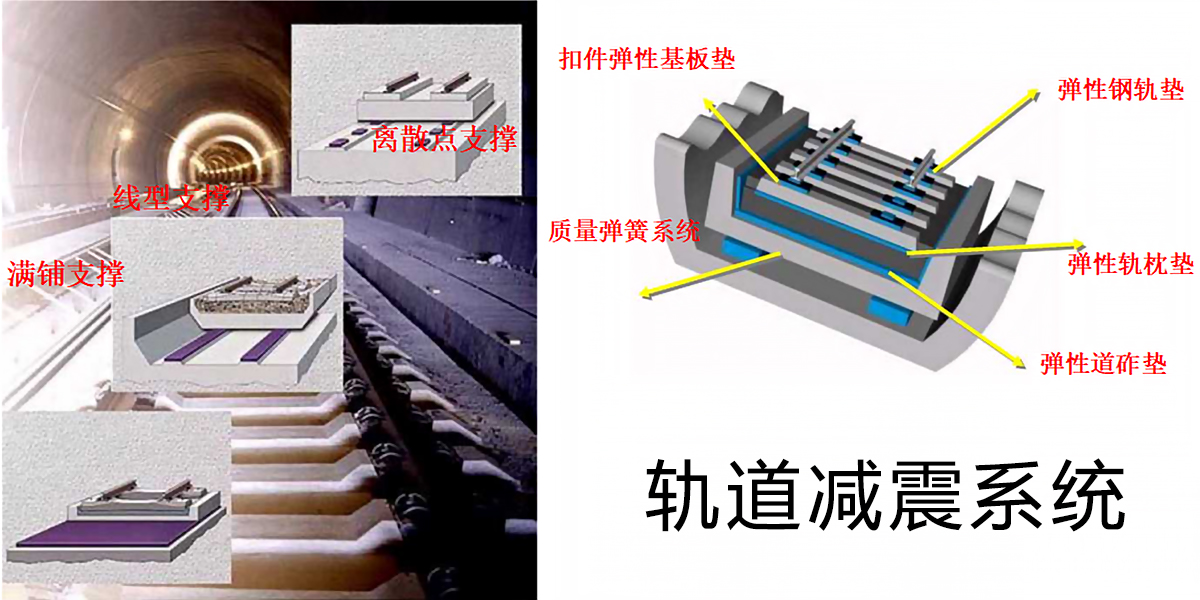

During the operation of urban rail transit, impact vibrations are generated between the train wheels and the rails. These vibrations are transmitted through the sleepers and the track bed to tunnel or bridge foundations, and further propagate and affect surrounding buildings and sensitive equipment. The structures of affected buildings can amplify the vibration excitations generated by locomotives, potentially causing damage to the building structures, such as settlement or cracks. Vibratec® polyurethane elastic pads can be used for vibration isolation of track beds under both compressive and shear loads, as well as for industrial equipment vibration isolation. Based on project characteristics and vibration reduction requirements, Vibrotech provides polyurethane vibration isolation pad systems with discrete support, linear support, and full-floor support solutions.

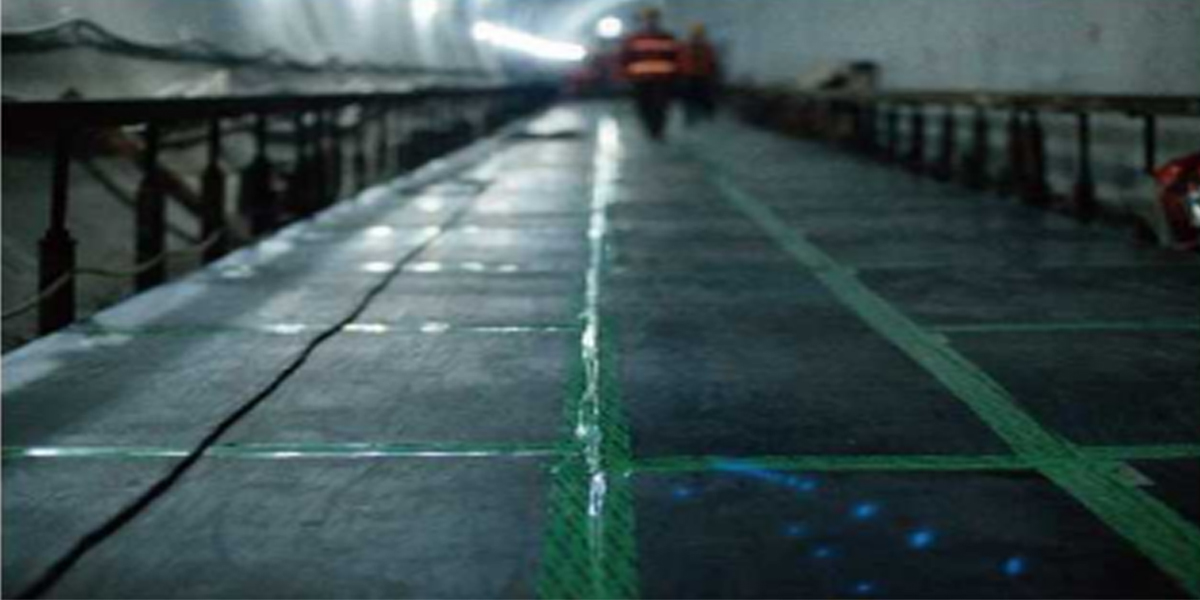

Before laying the track bed vibration isolation pad

After the track bed vibration isolation pads are laid

Rail trackbed rail laying

After the track bed vibration isolation pads are laid

Effect after laying strip vibration isolation pads

Effect of Laying Rail PU Vibration Isolation Pads

Polyurethane vibration isolation pads exhibit minimal plastic deformation under working loads, and their mechanical characteristics are relatively insensitive to load. The permanent compression deformation of polyurethane vibration pads is less than 5%, ensuring stable performance over long-term use.

1

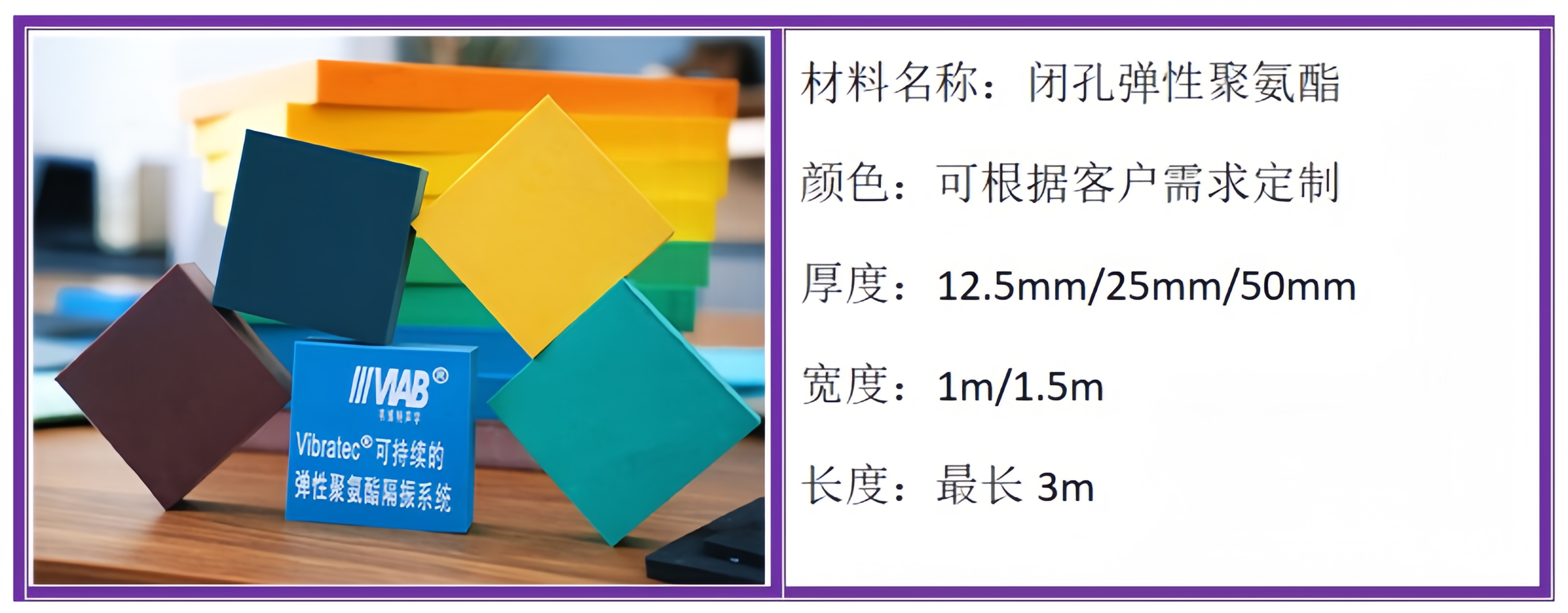

Closed-cell polyurethane elastomers are waterproof and moisture-proof, do not deteriorate or rot, and can resist corrosion from various chemicals, such as gasoline, mineral oil, and mineral grease.

2

• Material performance changes less than 10% after 10 million fatigue tests

• Excellent hydrolysis resistance and protection against bacterial erosion

» High wear resistance » Excellent tensile and tear strength » High deformation recovery » High resilience » Low abrasion rate » Measured insertion loss up to 15dB

4