4008-693-698

中文版

4008-693-698

中文版

4008-693-698

中文版

4008-693-698

中文版

We may have overlooked the fact that the sounds of children bouncing balls, playing marbles, and throwing objects hitting the floorboards, as well as the unavoidable sounds of furniture moving and footsteps in home life, can indeed cause trouble and harm to the lives of neighbors downstairs.

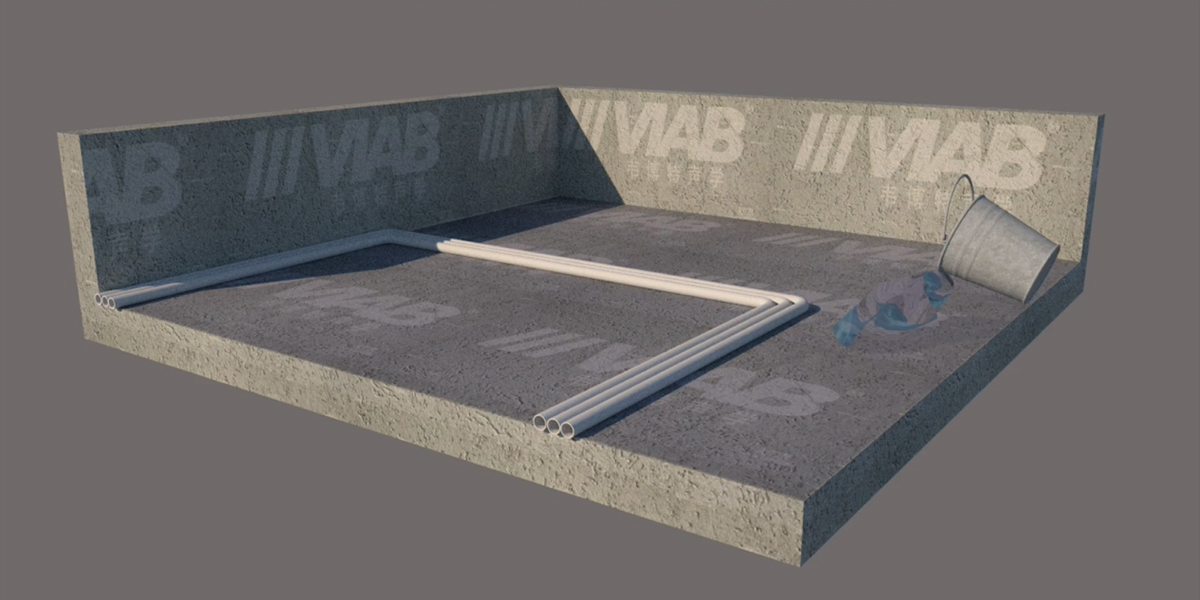

1. Clean the floor and sprinkle water to wet it

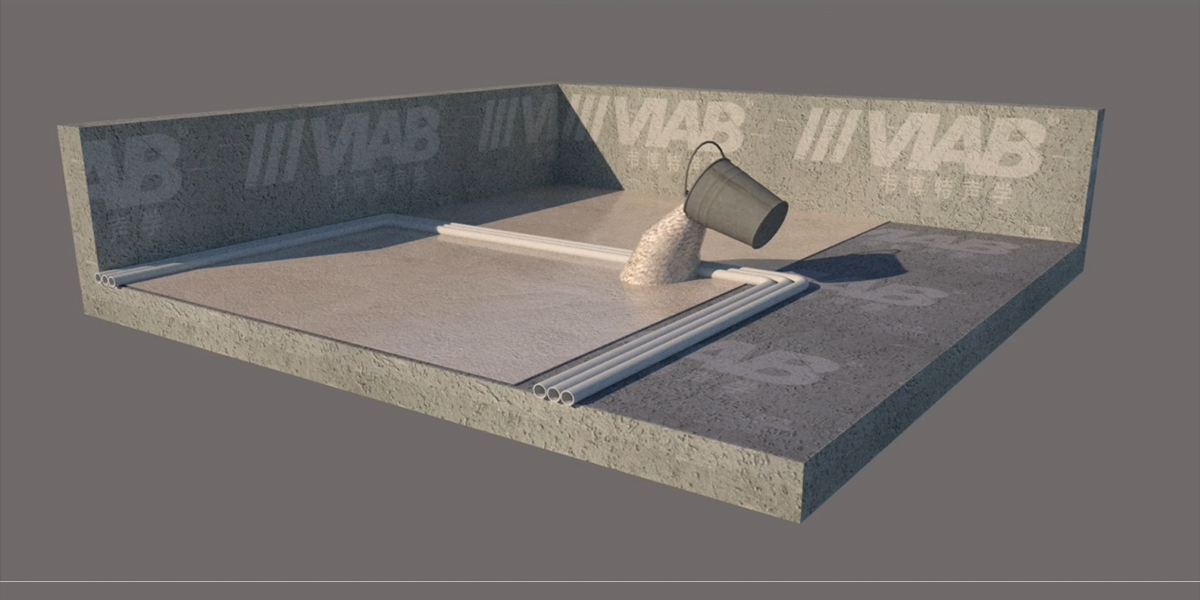

2. Apply and spread adhesive mortar glue

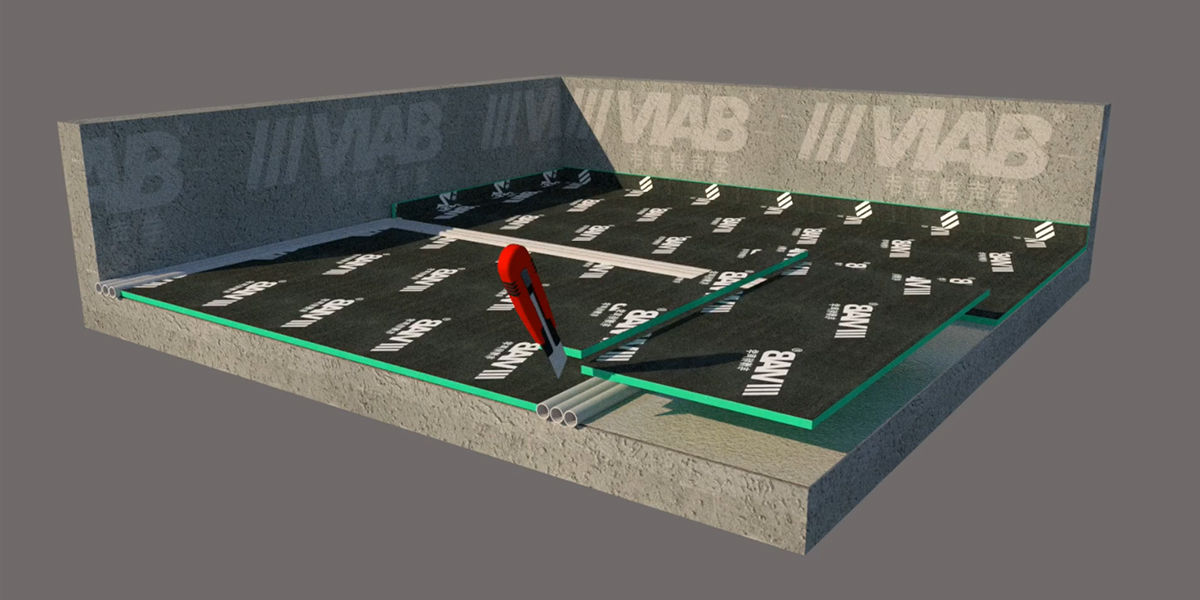

3. Cut and lay sound insulation pads according to the specified size

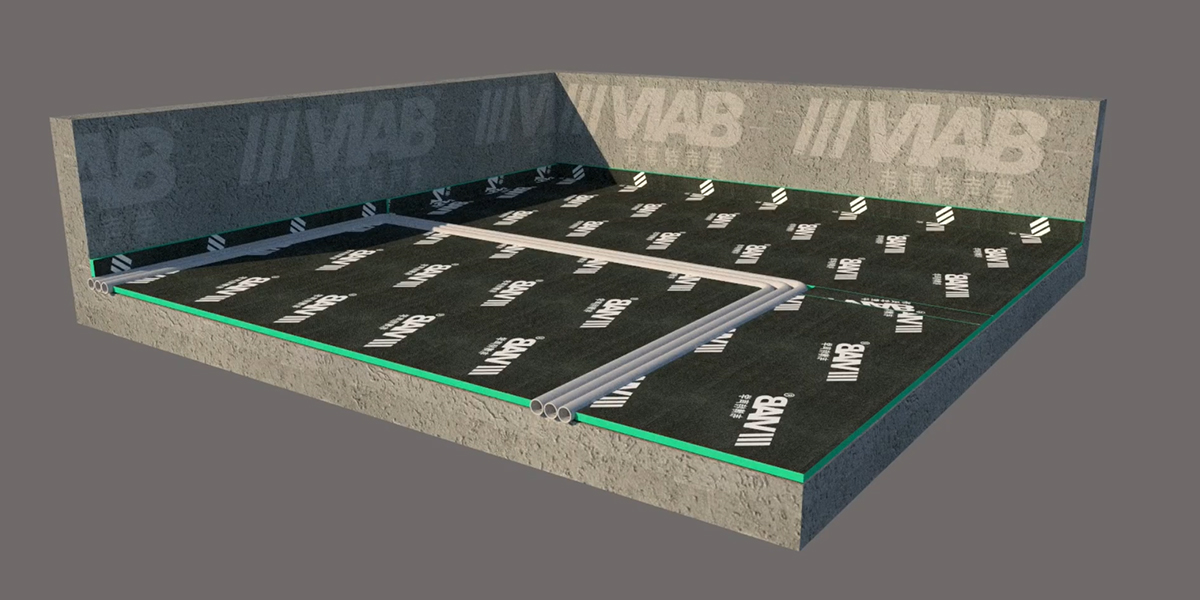

4. Lay the soundproof pad and turn up the edges at the corners of the wall

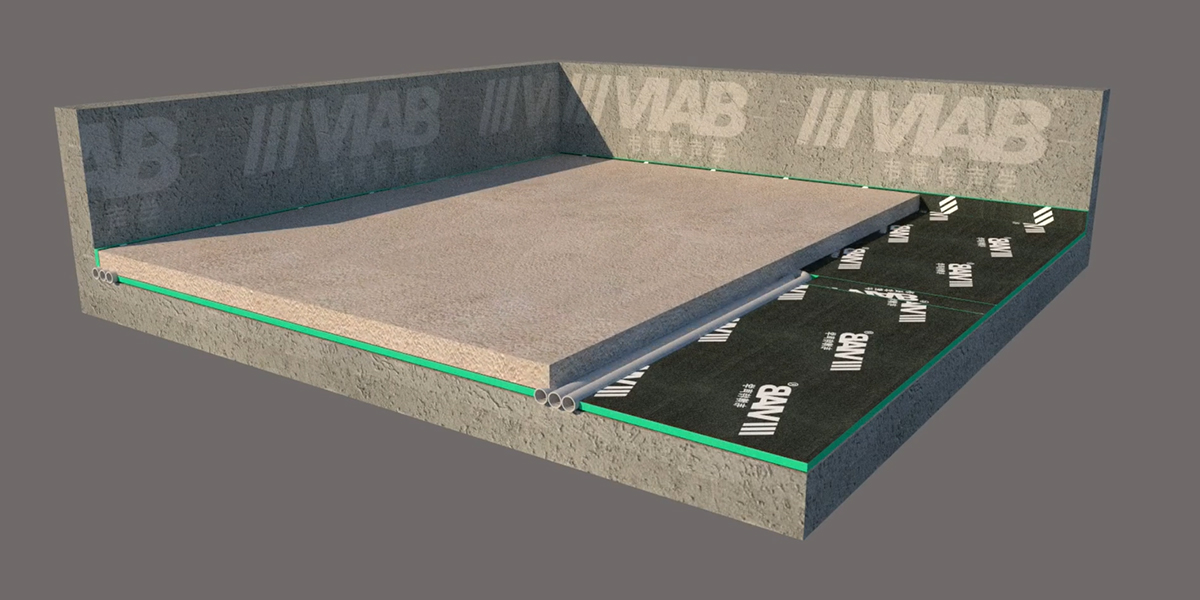

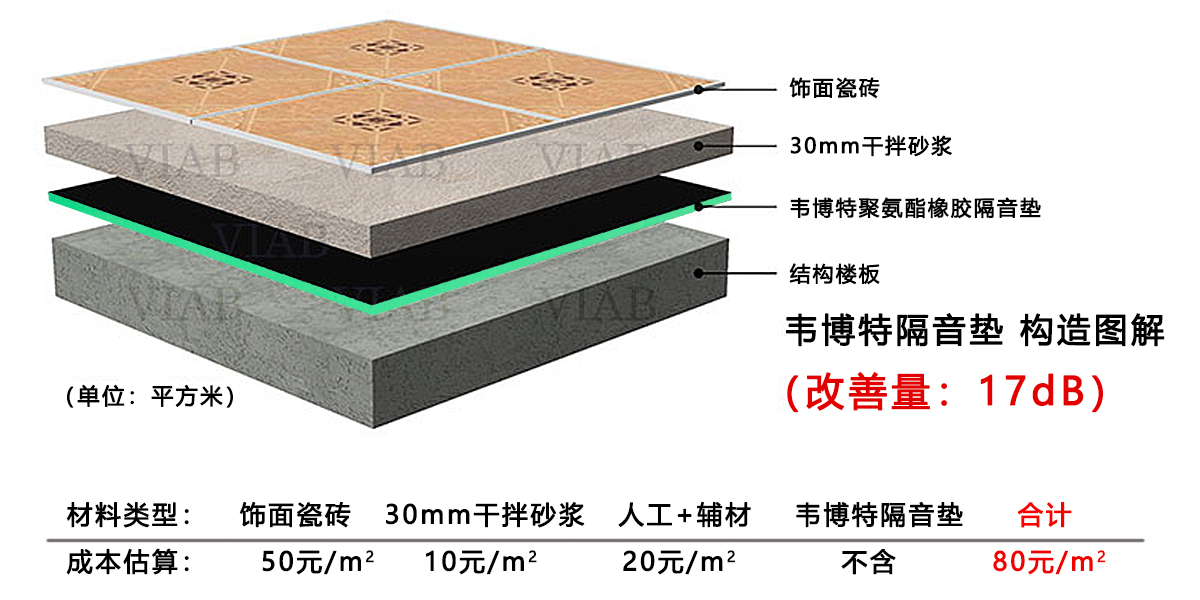

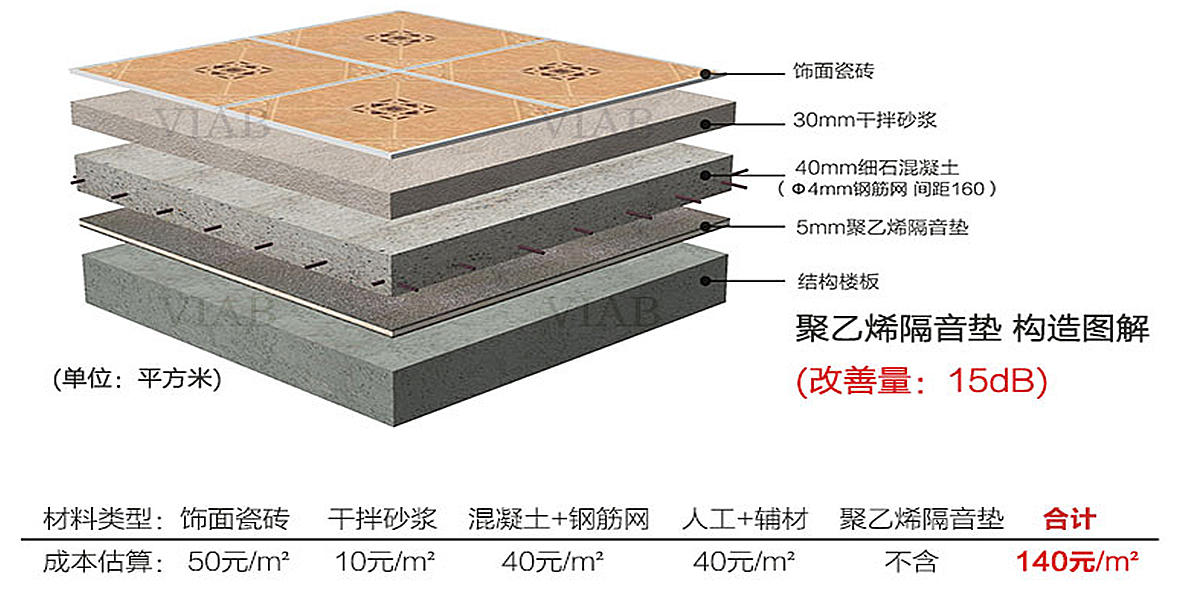

5. Lay a layer of 30mm-thick dry-mixed mortar

6. Laying floor tiles and decorative wood flooring

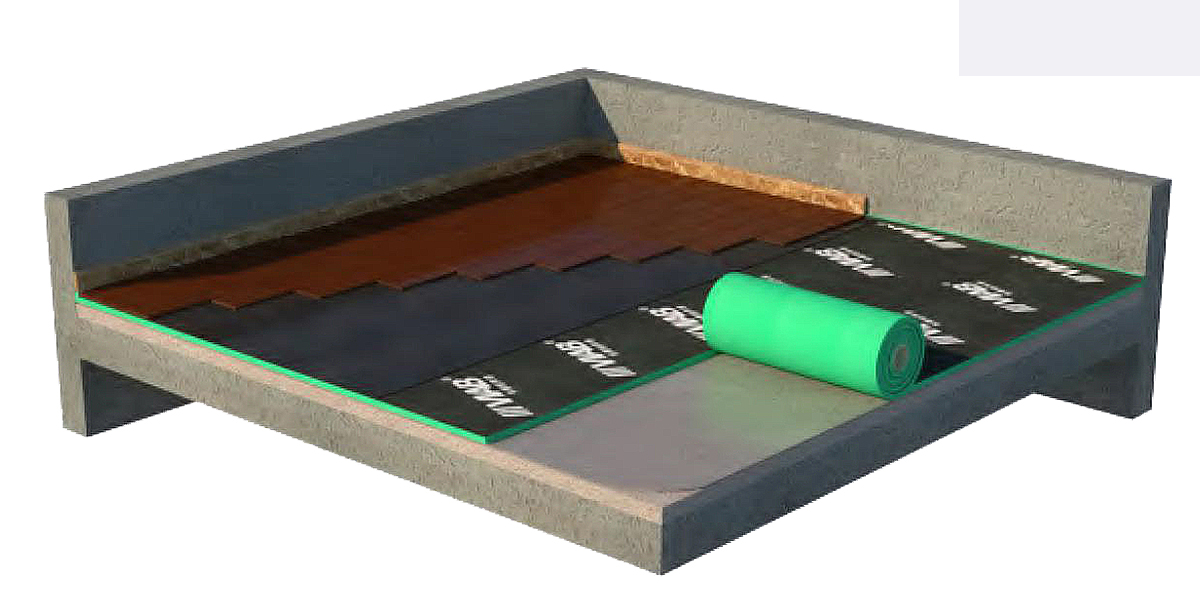

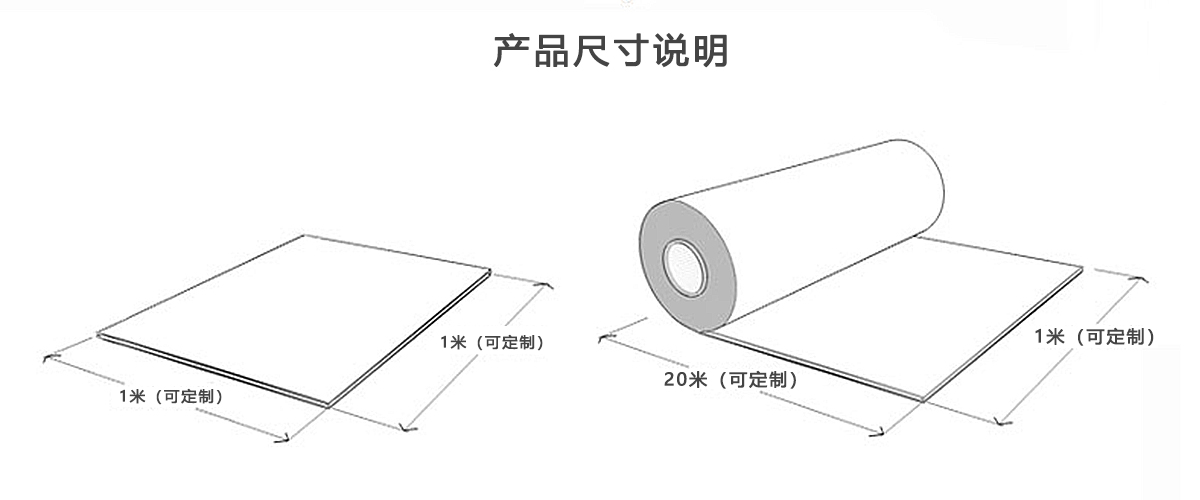

* For Wood Floor Applications: Lay the "Polyurethane Sound Insulation & Vibration Damping Mat" beneath the wood flooring. The increase in floor structure height equals the material thickness (CDM-A15: 1.5mm).

* For Tile Floor Applications: Lay the "Polyurethane Sound Insulation & Vibration Damping Mat" beneath the tile mortar bed. The mortar layer thickness should be ≥30mm. The increase in floor structure height equals the material thickness plus the mortar layer thickness.

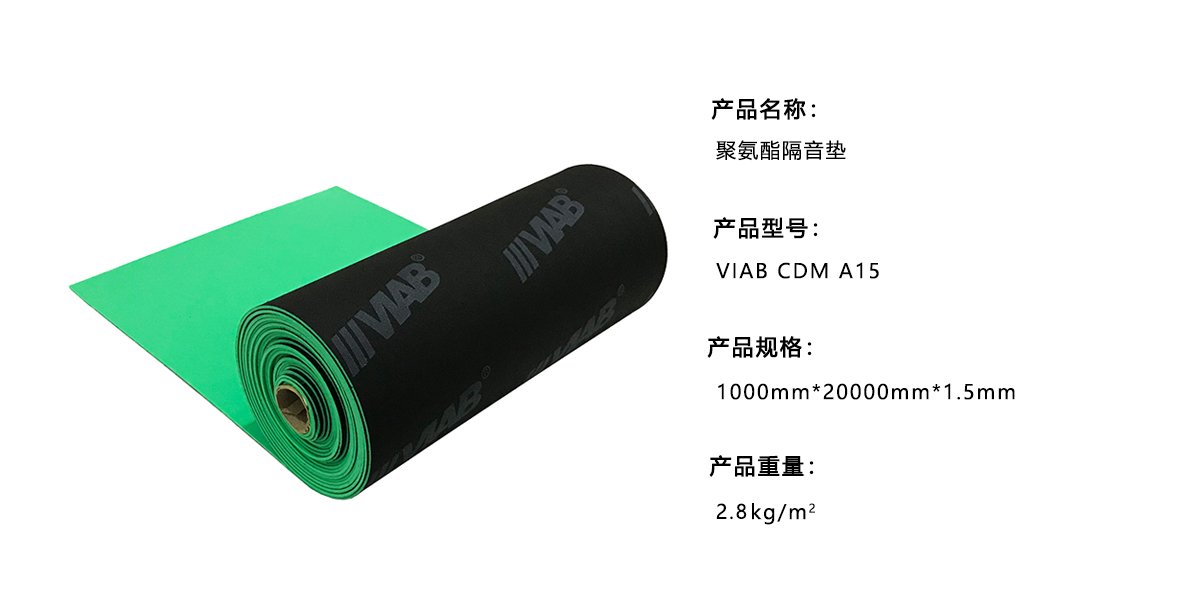

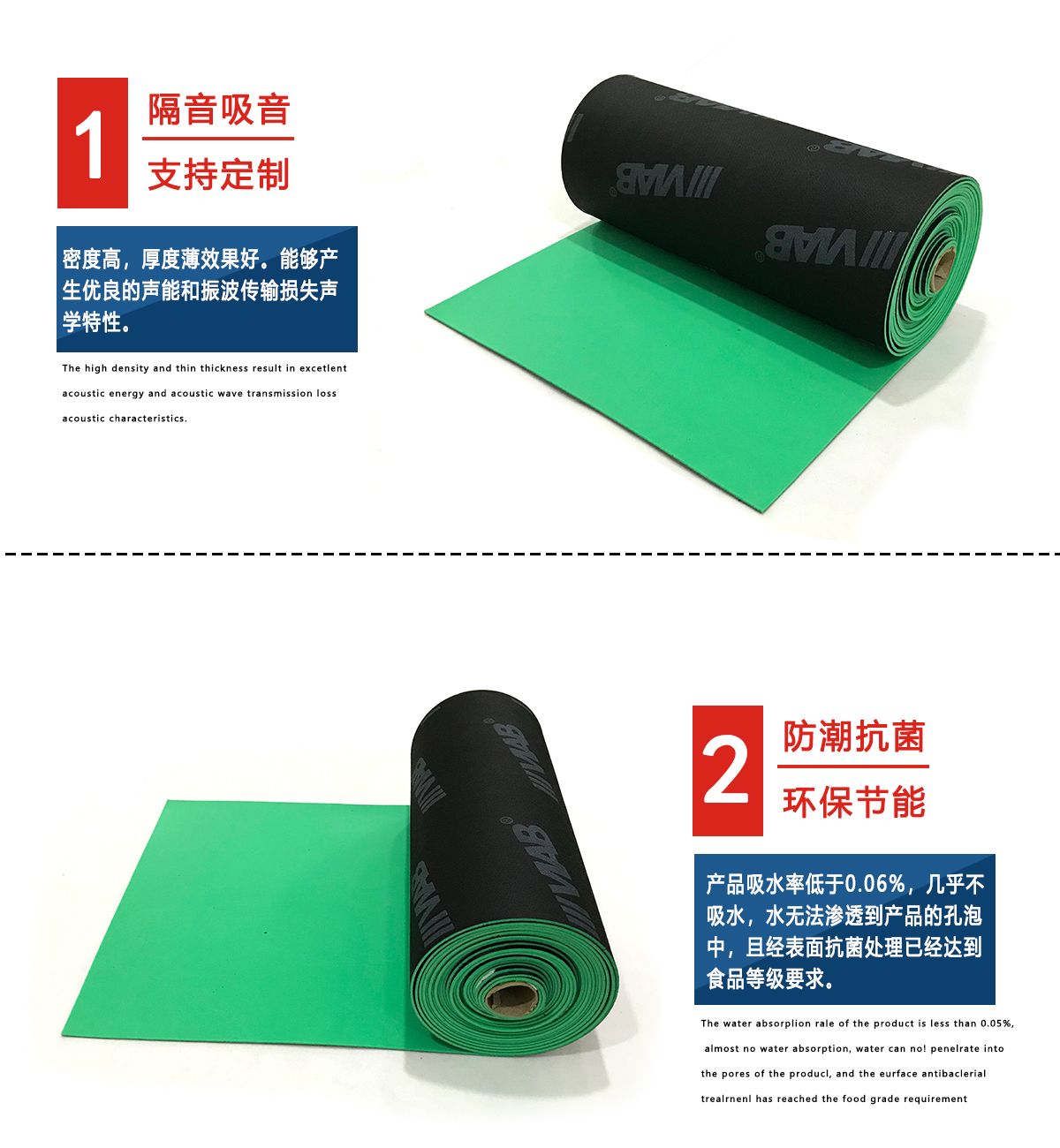

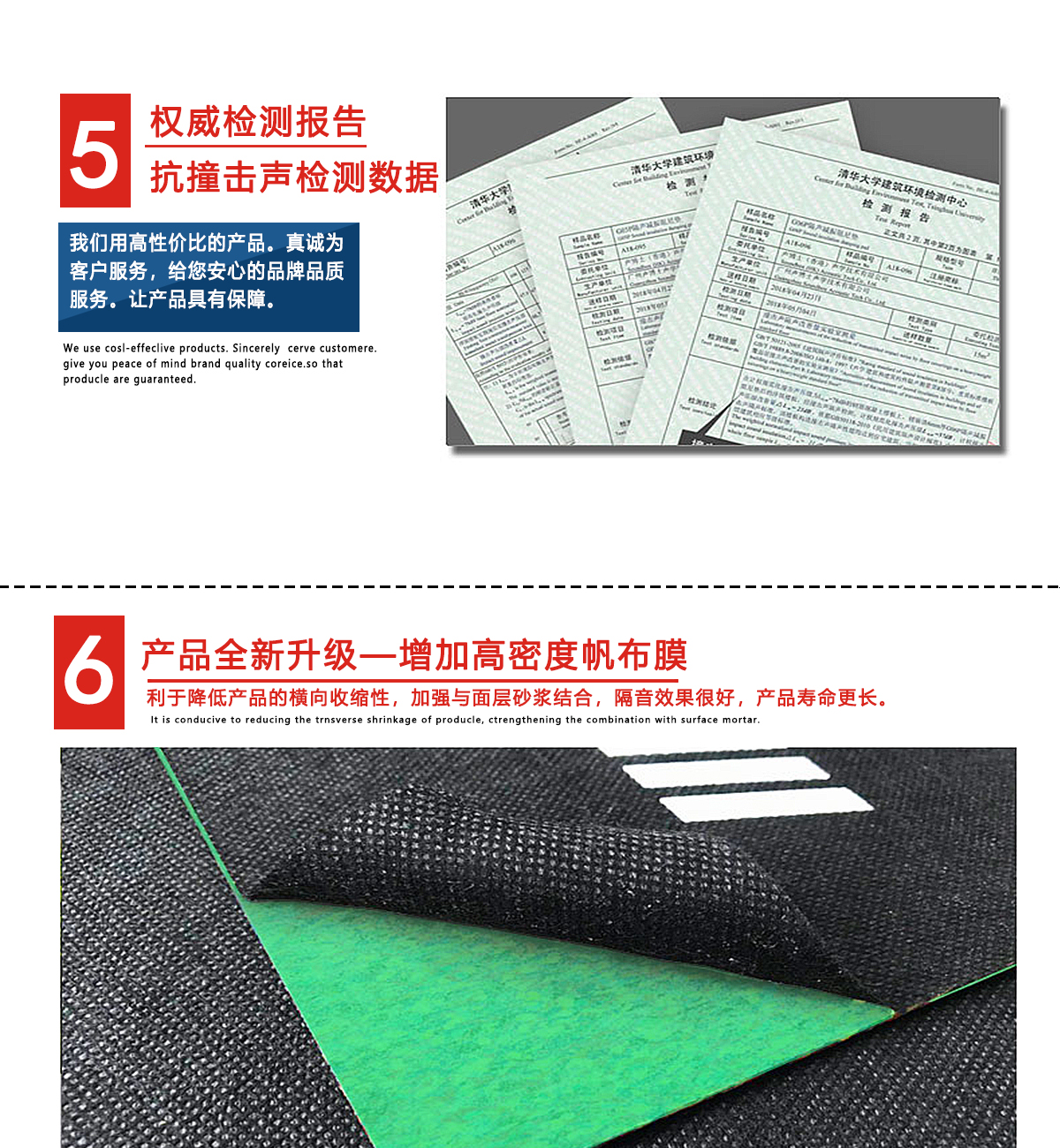

VIAB Vibratech Polyurethane Rubber Damping Vibration Isolation & Sound Insulation Mat utilizes eco-friendly polyurethane base material. The micro-cavity foam structure provides excellent physical properties including strong memory resilience and superior adhesion. Its broadband damping performance effectively reduces vibration wave transmission. When fully laid, it generates balanced and substantial surface support force. Applied as a floating underlayment for both wood and tile floors, it absorbs impact noise and breaks sound transmission bridges. The waterproof material does not degrade in humid environments, preventing mold growth and corrosion. It is free from harmful emissions and environmentally friendly.

Thanks to the high density of Vibratech soundproofing mats, a concrete layer is not required, thereby reducing the comprehensive unit cost.

1

Since Vibratech soundproofing mats eliminate the need for a concrete layer, they dry quickly after installation, thereby shortening the overall construction timeline.

2

The installation of Vibratech soundproofing mats is fast and efficient, as it eliminates the need for a concrete layer.

3

Vibratech soundproofing mats, manufactured using patented processes, deliver outstanding acoustic performance in sound absorption and noise reduction.

4